EG Pro (2 Component)

EG Pro is a two component, epoxy based tile grout available in a range of colours and suitable for all types of tiles and stones on the floor and wall. It has high chemical & abrasion resistance, and being impervious, it also produces hygienic joints that needs minimal maintenance. It is easy to apply and clean off, combining the performance of epoxy grouts with the ease of application associated with cement based grouts.

Related Products

Features & Benefits

- Non sag

- Hygienic and chemical resistant

- Stain and Fungi resistant

- Can be cleaned off from 15 minutes to 60 minutes after application

- Provides high strength and durable joints

- Suitable for submerged conditions

- Extremely easy to apply and to be cleaned from tiled surface

- Available in a range of colours

Product Details

Packaging

1 kg & 5 kg Kit

Uses

- Food preparation areas. Dairies, Kitchens & Cafeterias

- Showers, Swimming Pools, Bathrooms & Water bodies

- Hygiene sterile areas, Hospitals

- Industrial/Chemical plants

- Domestic areas & work tops

Coverage

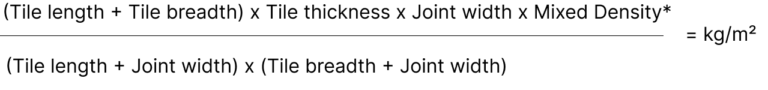

Consumption depend on joint width, size of tiles

Standards

- Exceeds EN 13888 requirements

- Tested in accordance with AATCC 30 PART 3

How to apply

Check potential staining risk: Apply grout to a few tiles/stones in a small trial area. If discolouration occurs or cleaning difficulty, apply a suitable sealer and repeat trial.

• Before commencing grouting, the adhesive bed must be set.

• The joints must be clean of all adhesive residue, dust or debris.

• Lightly sponge the tile surface to remove dust & dirt.

• Movement Joints: These should be provided in accordance with BS 5385: Part 1-5 and may be filled with the appropriate flexible sealant. Intermediate floor joints should be reinforced with brass or stainless steel. Use stainless steel where hygiene is essential.

Pour the content of PART B (Hardener) into the container of PART A (Resin) and mix well until a smooth paste is obtained. The use of a low speed electric drill is advantageous to get a homogeneous uniform coloured mix. Ensure that the mixed grout is used within its pot life/working time. This is reduced during at higher temperatures and extended at lower temperatures.

Using a hard rubber grout float, compact the mix into the joints ensuring that they are completely filled.

• Work in small areas and remove as much excess from the tile/stone surface as work proceeds. Strike off excess materials diagonally to the grout lines.

• Clean off during working time. Using a soft sponge with little cold water and applying gentle pressure, work in circular movement to emulsify the surface residues and provide uniform grout joints.

• After 15 minutes after application, check for joints to be stiff.

• Use a scrubber (for rustic & matt finish tiles) or sponge/clean cloth (for smooth tiles) dampened with clean water to scrub the tile surface in a circular motion diagonally to the grout lines in both clock-wise and anti-clock-wise directions.

• After 12 – 24 hours, clean the tiled surface with water and soap solution to remove any remaining light haze.

Tools and containers may be cleaned using water when the grout is still fresh. The hardened grout can be removed from tools mechanically.

Sold subject to the Company’s conditions of sale which are available on request.